Scrap briquetting machine is a kind of equipment used to compress various metal or non-metal waste into high-density blocks. It is widely used in the recycling industry, which can effectively reduce the volume of waste, facilitate transportation and storage, and improve the recycling rate of waste.

Customized :

YESApplication :

SCRAP RECYCLINGOrder(MOQ) :

1 SetLead Time :

30 DAYSShipping Port :

SHANGHAIProduct Origin :

CHINABriquetting Machine

Features

Precision Under Pressure

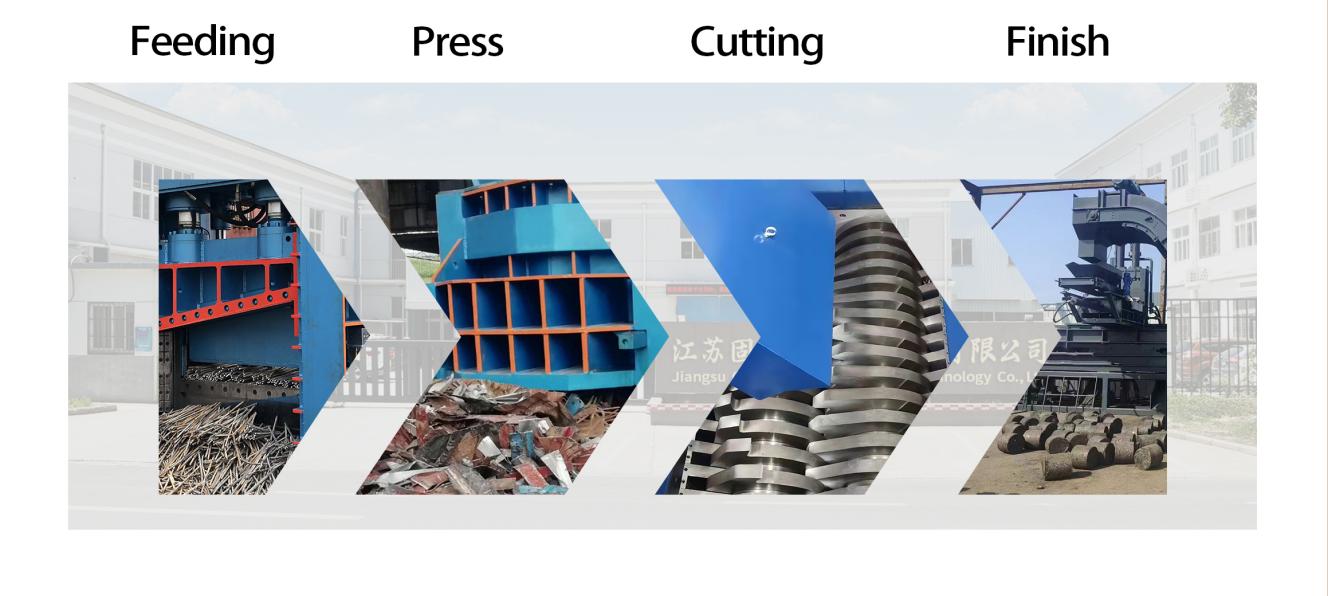

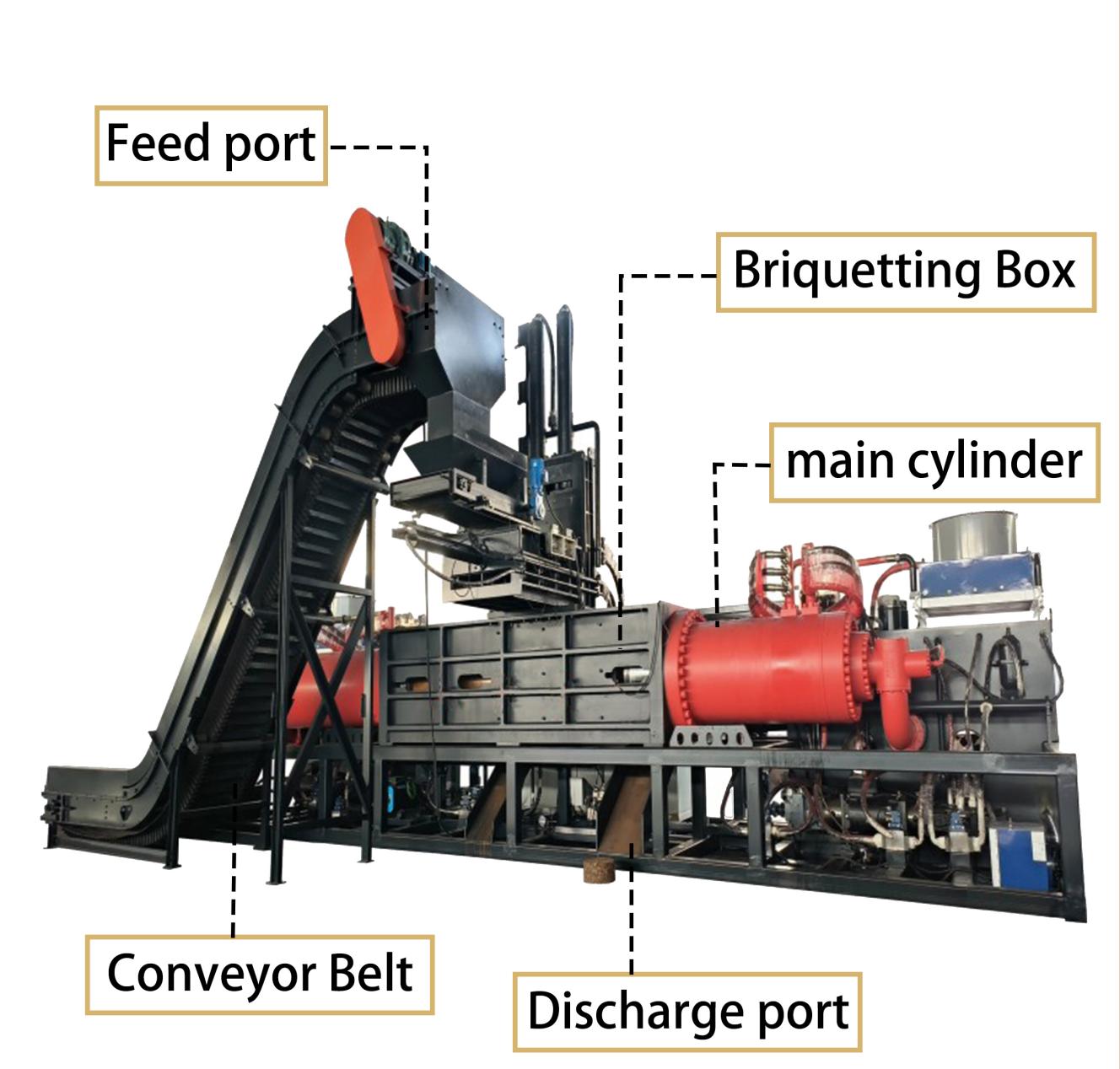

The waste briquetting machine is usually driven by a hydraulic system, which compresses the loose waste into dense blocks through strong pressure. Its workflow generally includes the following steps:

Feeding: The waste is fed into the briquetting machine's material box through a conveyor belt or manually.

Pre-pressing: The pre-pressing cylinder performs preliminary compression on the waste to reduce its volume.

Main pressure: The main pressure cylinder applies greater pressure to the pre-pressed waste to compress it into a high-density block.

Discharging: The compressed blocks are pushed out of the material box, completing the entire briquetting process.

Choose us for an efficient, durable, and worry-free cutting experience!

Working process

Parameter

| Y83-315 | Y83-500 | Y83-630 | Y83-1000 | Y83-1300 | Y83-1500 | Y83-2000 | Y83-3000 |

| 30KW | 37KW | 60KW | 283.5KW | 323.5KW | 374.9KW | 464.9KW | 3773.9KW |

| 1-3T/H | 2-5T/H | 3-6T/H | 14-19T/H | 16-22T/H | 18-25T/H | 22-30T/H | 45-55T/H |

| Cast iron,steel,aluminum, red copper and brass | Cast iron,steel,aluminum, red copper and brass | Cast iron,steel,aluminum, red copper and brass | Crushed material of cast iron.steel.aluminium.copper and brass | Crushed material of cast iron.steel.aluminium.copper and brass | Crushed material of cast iron.steel.aluminium.copper and brass | Crushed material of cast iron.steel.aluminium.copper and brass | Crushed material of cast iron.steel.aluminium.copper and brass |

Details

Application Areas

Video Showcase

FAQ

1. What is a scrap baling machine used for?

It compresses waste materials (such as metal scraps, plastics, and paper) into compact bales, reducing volume for easier transportation and recycling.

2. What types of waste can it process?

It handles various waste types, including metal scraps, plastics, paper, textiles, and more.

3. What are the benefits of using a baling machine?

Saves space, reduces transportation costs, improves recycling efficiency, and is environmentally friendly.

4. Is it complicated to operate?

Designed with automation, it’s user-friendly and easy to operate.

5. How to choose the right baling machine?

Select based on the type of waste, production needs, and budget.