The stamping die set inside the scrap metal briquetting machine is a key component of the equipment, designed for efficient compression of various scrap metal materials (such as steel, copper, aluminum, etc.). The die set is made of high-strength alloy steel or special wear-resistant materials, and has excellent compression resistance, wear resistance and fatigue resistance after precision processing and heat treatment, and can withstand high load impact and long-term continuous operation.

Customized :

YESApplication :

SCRAP RECYCLINGOrder(MOQ) :

1 setLead Time :

30 DAYSShipping Port :

SHANGHAIProduct Origin :

CHINABriquetting Machine Mould

Features

Strength in every alloy

It is widely used in scrap metal recycling stations, steel processing plants, automobile dismantling centers and other places to compress loose scrap metal into high-density blocks, saving storage space and reducing transportation costs.

High Hardness: After heat treatment, the hardness of tool steel can reach 50-70 HRC, making it suitable for tools requiring high hardness.

Excellent Wear Resistance: Tool steel can maintain a long service life under high-wear conditions.

High Strength and Toughness: While maintaining high hardness, tool steel possesses a certain level of toughness, allowing it to withstand impact loads.

Good Heat Resistance: Some tool steels can retain high hardness and strength even in high-temperature environments.

Choose us for an efficient, durable, and worry-free cutting experience!

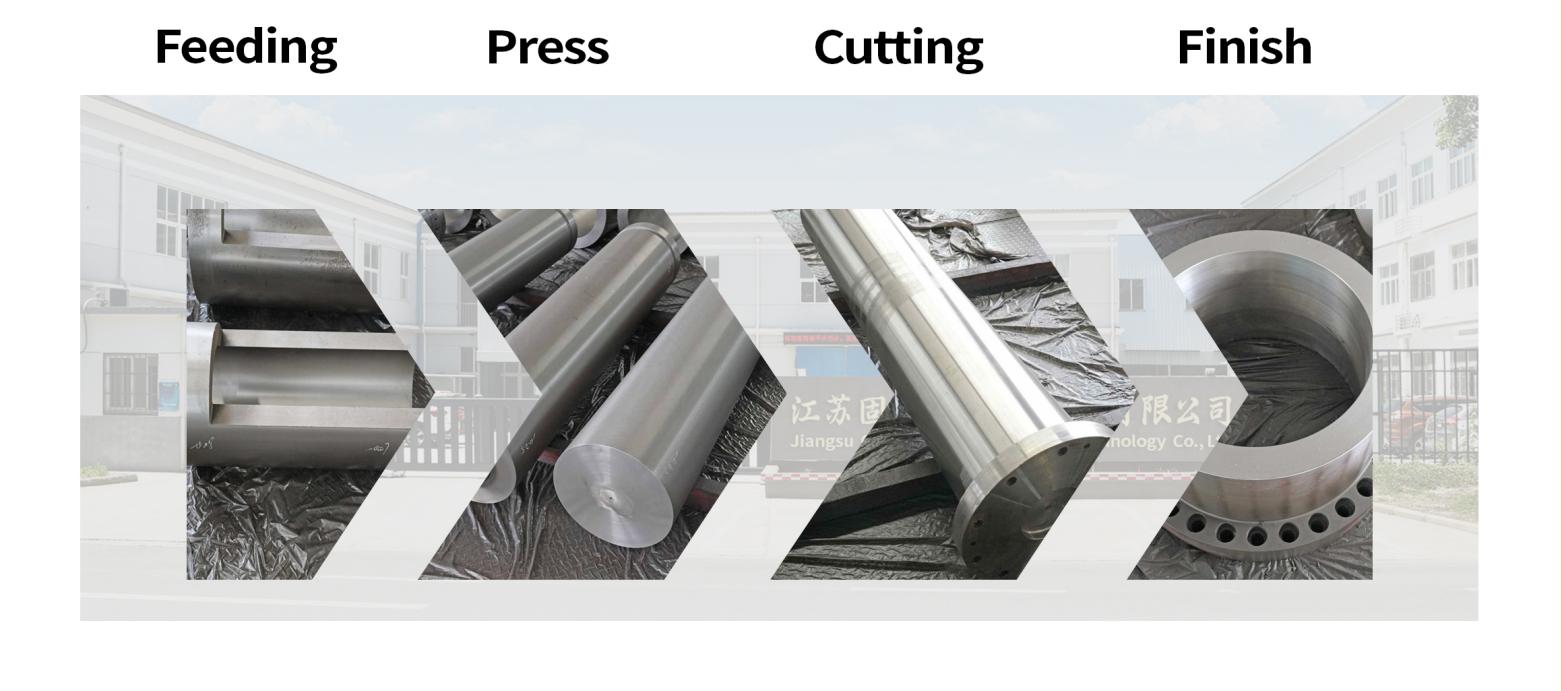

Working process

Parameter

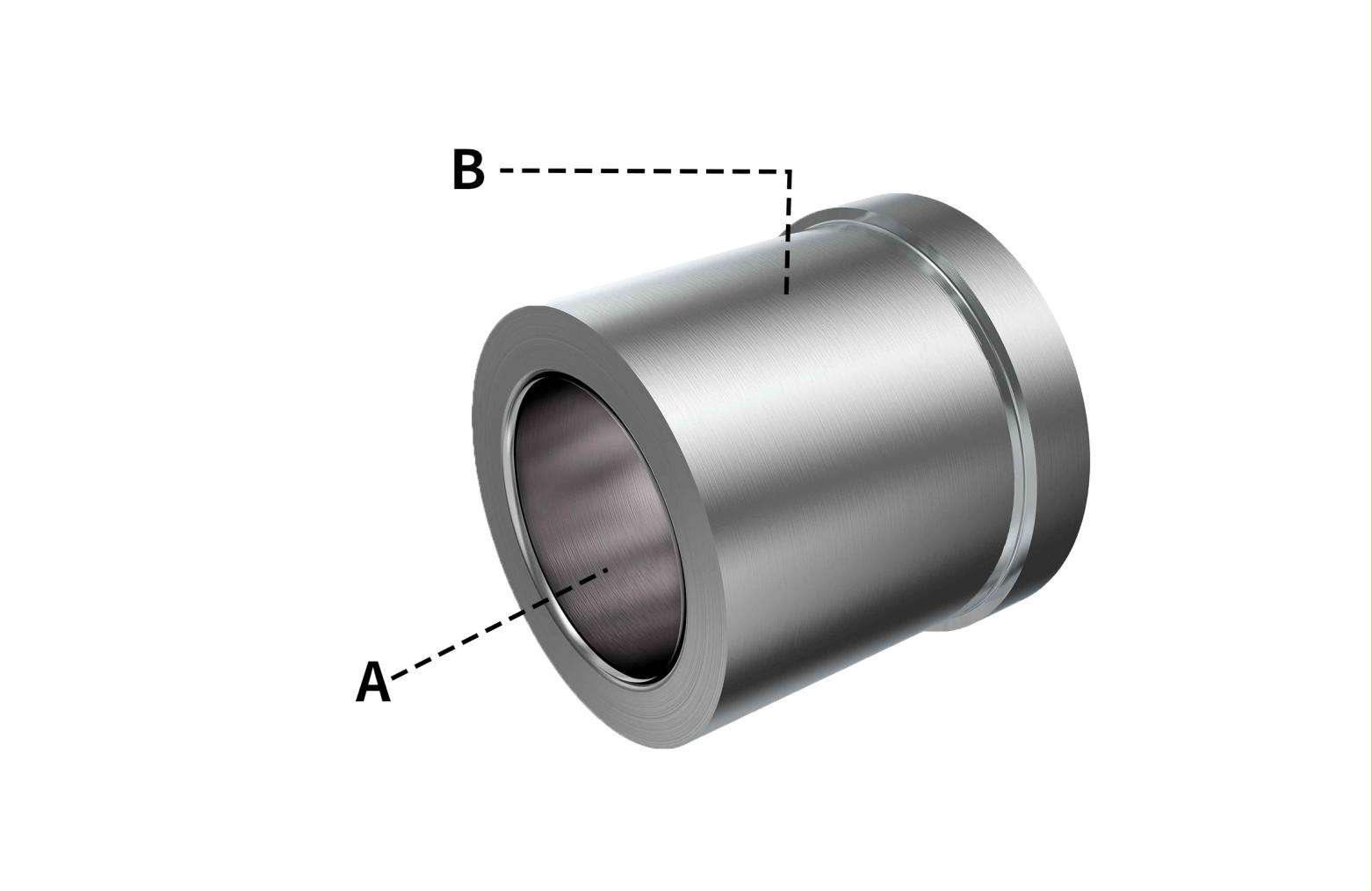

| Material | C | Si | Mn | Mo | V | P | S | Cr | Ni |

| A | 0.8 | 0.5 | 0.3 | 7.0 | 2.0 | 0.015 | 0.015 | 5.0 | 0.2 |

| B | 0.37 | 0.4 | 0.5 | 0.2 | 0.1 | 0.01 | 0.005 | 1.0 | 0.2 |

The data in the chart are measured values and may have fluctuating differences.

Details

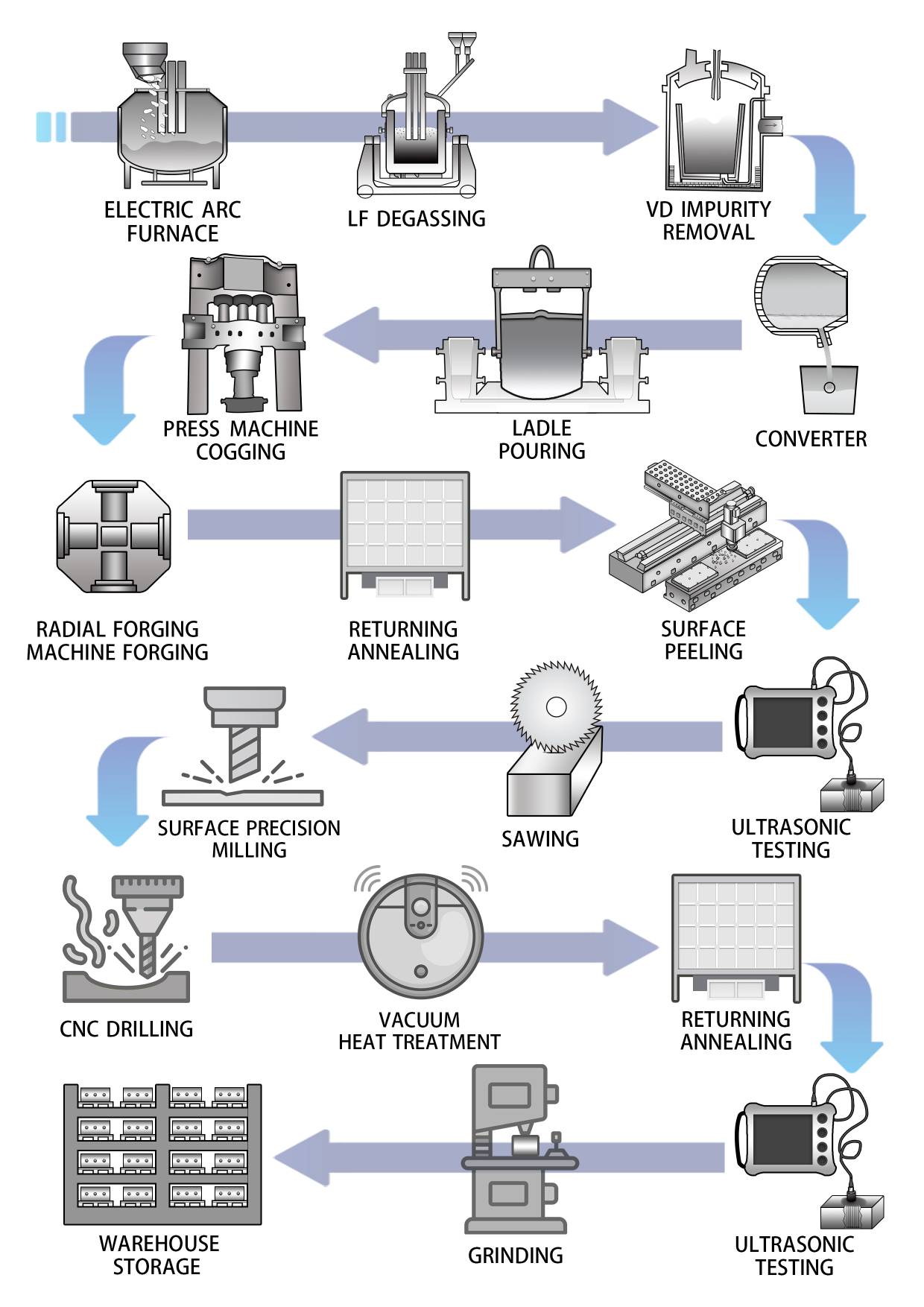

Technology

1. What is mold steel?

Mold steel is a specialized type of steel used for manufacturing molds (such as stamping, forging, and die-casting molds). It possesses high hardness, strength, wear resistance, toughness, and dimensional stability.

2. What are the main types of mold steel?

Cold work mold steel:Used for room-temperature molds, such as stamping molds (common grades: Cr12, Cr12MoV).

Hot work mold steel:Used for high-temperature molds, such as die-casting molds (common grades: H13, 5CrNiMo).

3. How to choose the right mold steel?

Selection should consider factors such as mold type, working conditions (temperature, stress, wear), processing techniques, and cost.

4. How to extend the service life of mold steel?

Choose the right material and optimize design.

Follow standardized processing and ensure proper usage, avoiding overloading and performing regular maintenance.

5. What are the development trends in mold steel?

High performance:Improve hardness, strength, wear resistance, and fatigue resistance.

High precision: Enhance dimensional accuracy and surface quality.

Green and environmentally friendly: Develop low-alloy, pollution-free mold steel.