The 400T Scrap Baling Machine is a specialized piece of equipment used for high-density compression and baling of various loose metallic or non-metallic waste materials, widely applied in the recycling and renewable resources industry. With its 400-ton hydraulic compression system, the machine provides strong, stable force capable of efficiently compressing bulky, lightweight, or irregularly shaped scrap into uniform, tightly packed bundles or blocks.

Customized :

YESApplication :

SCRAP RECYCLINGOrder(MOQ) :

1 SetLead Time :

30 DAYSShipping Port :

SHANGHAIProduct Origin :

CHINABaling Machine

Features

Precision Under Pressure

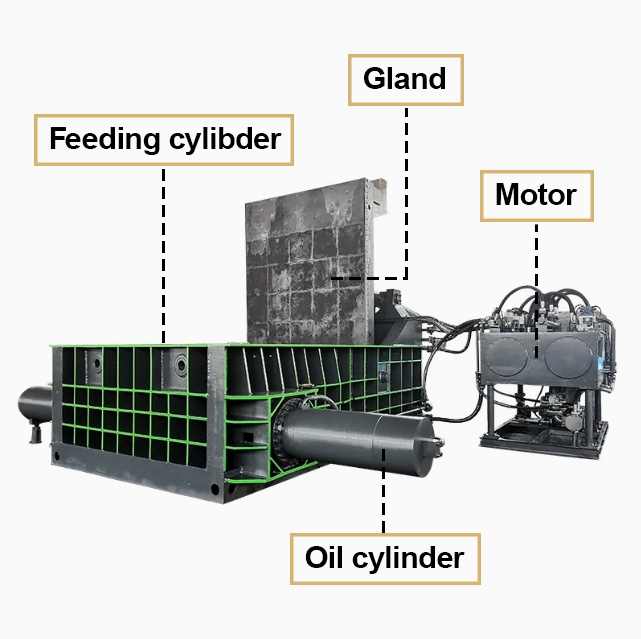

The Baling Machine is typically powered by a robust hydraulic system that applies strong, stable pressure to compress loose materials into compact, high-density bales. Designed for efficiency and reliability, it plays a vital role in modern recycling and waste-handling operations.

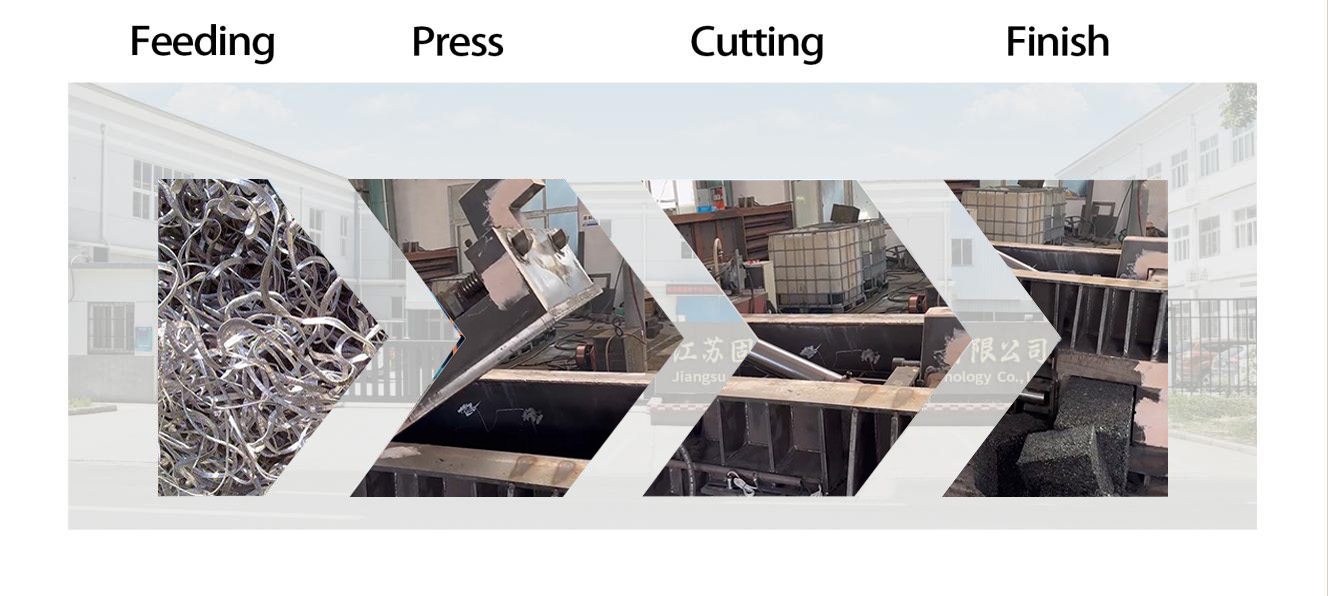

Feeding: Various waste materials are fed into the baling chamber either manually or via a conveyor system, ensuring a smooth and continuous operation.

Pre-pressing: The pre-pressing mechanism initially compresses the loose materials, significantly reducing their volume and preparing them for further compaction.

Main pressure: The main hydraulic ram applies higher pressure to the pre-compressed materials, forming tight, uniform bales with high density and stability.

Discharging: Once the baling process is complete, the finished bale is automatically or hydraulically ejected from the chamber, ready for transportation or storage.

With its high efficiency, durable structure, and user-friendly operation, the Baling Machine helps reduce waste volume, lower logistics costs, and improve recycling efficiency. Choose us for a powerful, durable, and worry-free baling solution that delivers consistent performance you can rely on.

Working process

Parameter

| Y81-200 | Y81-250 | Y81-315 | Y81-400 | Y81-500 | Y81-630 | Y81-800 | Y81-1000 |

| 30KW | 45KW | 55KW | 75KW | 90KW | 75+37KW | 75+75KW | 90+90KW |

| 200*300mm | 500*500 | 600*600 | 700*700 | 700*700 | 700*700 | 700*700 | 45-55T/H |

| Cast iron,steel,aluminum, red copper and brass | Cast iron,steel,aluminum, red copper and brass | Cast iron,steel,aluminum, red copper and brass | Crushed material of cast iron.steel.aluminium.copper and brass | Crushed material of cast iron.steel.aluminium.copper and brass | Crushed material of cast iron.steel.aluminium.copper and brass | Crushed material of cast iron.steel.aluminium.copper and brass | Crushed material of cast iron.steel.aluminium.copper and brass |

Details

Application Areas

Video Showcase

FAQ

1. What is a scrap baling machine used for?

It compresses waste materials (such as metal scraps, plastics, and paper) into compact bales, reducing volume for easier transportation and recycling.

2. What types of waste can it process?

It handles various waste types, including metal scraps, plastics, paper, textiles, and more.

3. What are the benefits of using a baling machine?

Saves space, reduces transportation costs, improves recycling efficiency, and is environmentally friendly.

4. Is it complicated to operate?

Designed with automation, it’s user-friendly and easy to operate.

5. How to choose the right baling machine?

Select based on the type of waste, production needs, and budget.