Alloy spring steel has high mechanical properties and process properties. Elements such as Si, Mn, Cr, and V are added to it to refine the grains, improve the strength and elastic limit of the steel, and enable it to withstand greater loads and deformations.

Customized :

YESApplication :

SCRAP RECYCLINGOrder(MOQ) :

1 TONLead Time :

30 DAYSShipping Port :

SHANGHAIProduct Origin :

CHINAHIGH QUALITY ALLOY MOLD STEEL

Features

Strength in every alloy

Alloy spring steel refers to a type of steel that enhances its mechanical and processing properties by adding alloying elements (such as silicon, manganese, chromium, vanadium, etc.).

High Strength and Elastic Limit:The addition of alloying elements refines the grain structure, improving the steel's strength and elastic limit, enabling it to withstand greater loads and deformation.

Excellent Fatigue Performance:After proper heat treatment, alloy spring steel exhibits high fatigue strength, allowing it to endure repeated stress cycles without fracturing easily.

Good Hardenability:Alloying elements improve the steel's hardenability, enabling it to achieve a uniform martensitic structure across larger cross-sections, ensuring consistent performance of the spring.

Good Plasticity and Toughness:While maintaining strength, alloy spring steel also possesses a certain degree of plasticity and toughness, allowing it to withstand impact loads.

High Surface Quality: Alloy spring steel typically requires high surface quality to reduce stress concentration and enhance fatigue life.

Choose us for an efficient, durable, and worry-free cutting experience!

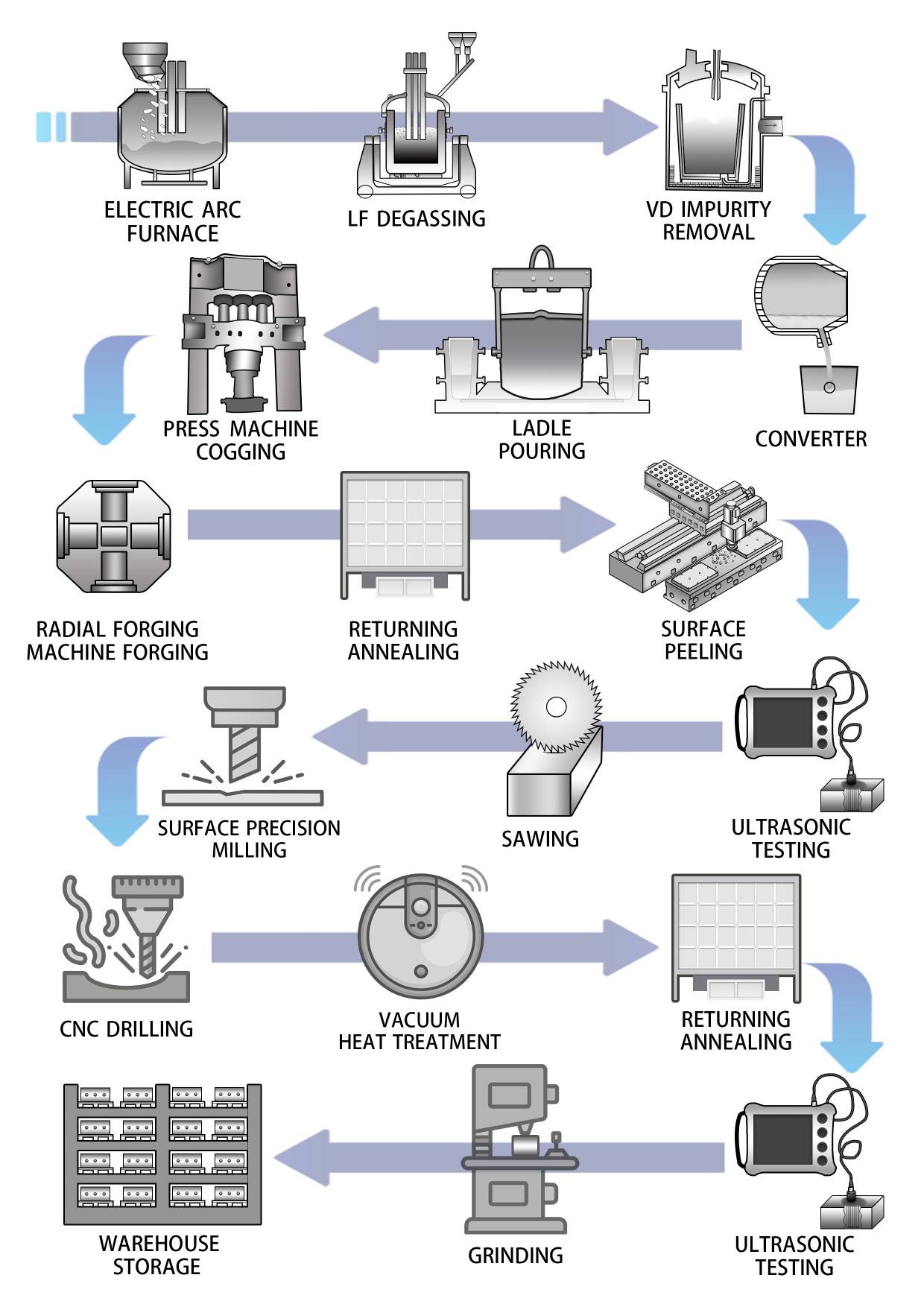

Working process

Parameter

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo | V |

| 60Si2Mn | 0.64 | 2 | 0.9 | 0.035 | 0.035 | 0.035 | 0.035 | 0 | 0 |

The data in the chart are measured values and may have fluctuating differences.

Details

Technology

1. What is mold steel?

Mold steel is a specialized type of steel used for manufacturing molds (such as stamping, forging, and die-casting molds). It possesses high hardness, strength, wear resistance, toughness, and dimensional stability.

2. What are the main types of mold steel?

Cold work mold steel:Used for room-temperature molds, such as stamping molds (common grades: Cr12, Cr12MoV).

Hot work mold steel:Used for high-temperature molds, such as die-casting molds (common grades: H13, 5CrNiMo).

3. How to choose the right mold steel?

Selection should consider factors such as mold type, working conditions (temperature, stress, wear), processing techniques, and cost.

4. How to extend the service life of mold steel?

Choose the right material and optimize design.

Follow standardized processing and ensure proper usage, avoiding overloading and performing regular maintenance.

5. What are the development trends in mold steel?

High performance:Improve hardness, strength, wear resistance, and fatigue resistance.

High precision: Enhance dimensional accuracy and surface quality.

Green and environmentally friendly: Develop low-alloy, pollution-free mold steel.